Case Study Location:

- Manhattan,

- New York

- Case Study Topic: Foundation Repair/Retrofit

Project Specs:

- Location: Manhattan – New York, NY

- Certified Installer: FSR

- Engineer of Record (EOR): Blue Sky Design, Inc.

- Helical Pile Specifications:

– 10 MacLean Power Systems (MPS) Helical Piles

– D6 (1.5″ Round Corner Square) Lead w/ 8”, 8”, 8” Dia. Helices on a 7″ shaft & D6 Extensions

– Average Depth of Helical Piles: 22’

– Minimum Req’d Torque of Perimeter Piles: 2,500 ft-lbs

– Minimum Req’d Torque of Interior Piles: 5,000 ft-lbs - Ultimate Load(s):

– 25 kips @ Perimeter Helical Piles

– 50 kips @ Interior Helical Piles

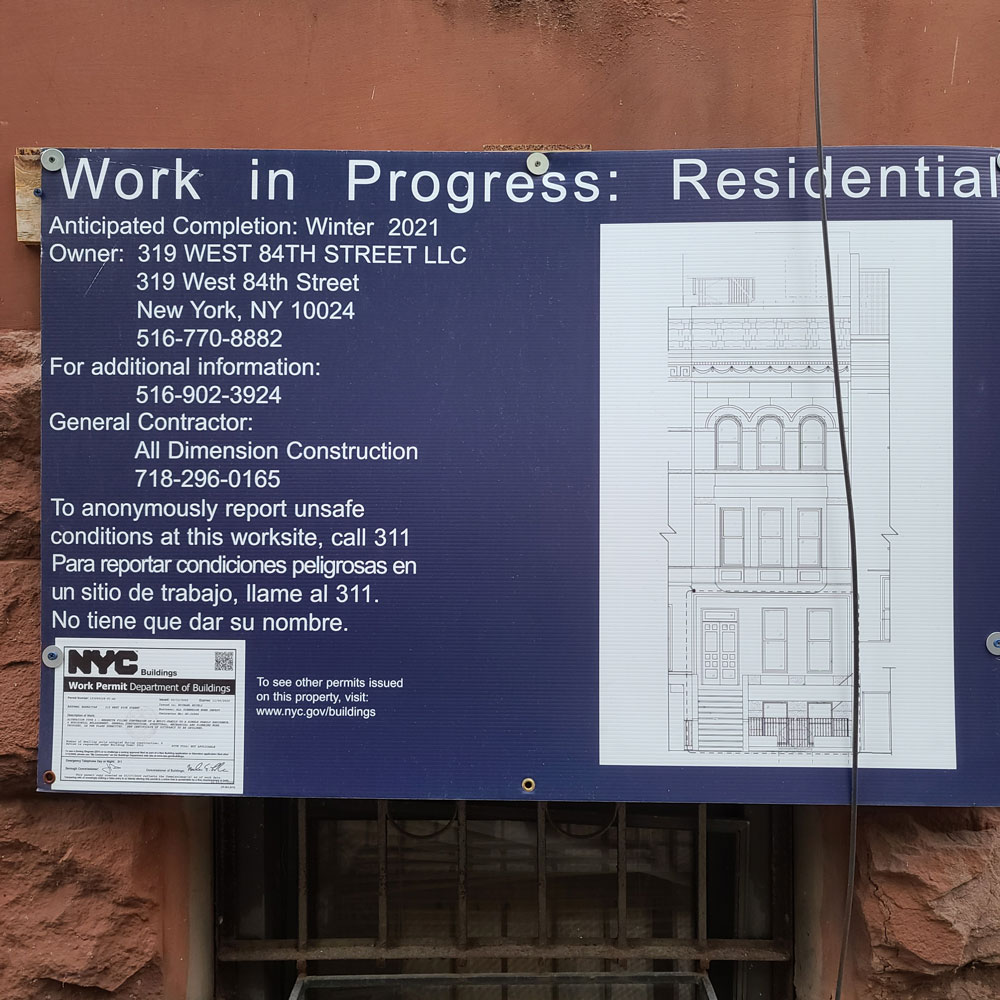

An extension was being added to the rear of an aging brownstone on West 84th Street in Manhattan. The only way to access the site was through a 36” wide doorway at the front of the building. FSR, with their vast selection of helical pile installation equipment, was able to quickly put their Bobcat MT 100 walk-behind into action, enabling them to access the rear yard and install the helical piles. 10 MacLean Power Systems (MPS) helical piles, consisting of 1.5” round corner square shaft (RCS) were to be installed to an average depth of 22’.

The perimeter piles were installed to a minimum torque of 2,500 ft-lbs and the interior piles were installed to a minimum of 5,000 ft-lbs. During the installation, some large rock formations were encountered, causing difficulties with the pile’s penetration. With some quick thinking and several discussions with the engineer of record, FSR modified the helical lead section there by allowing the lead to bypass the obstructions and achieve the desired depth. Several piles were installed to the top of bedrock as shown on the soil borings. Once the engineer approved the suitability and load bearing capacity of the bedrock, those piles were reclassified as end bearing.